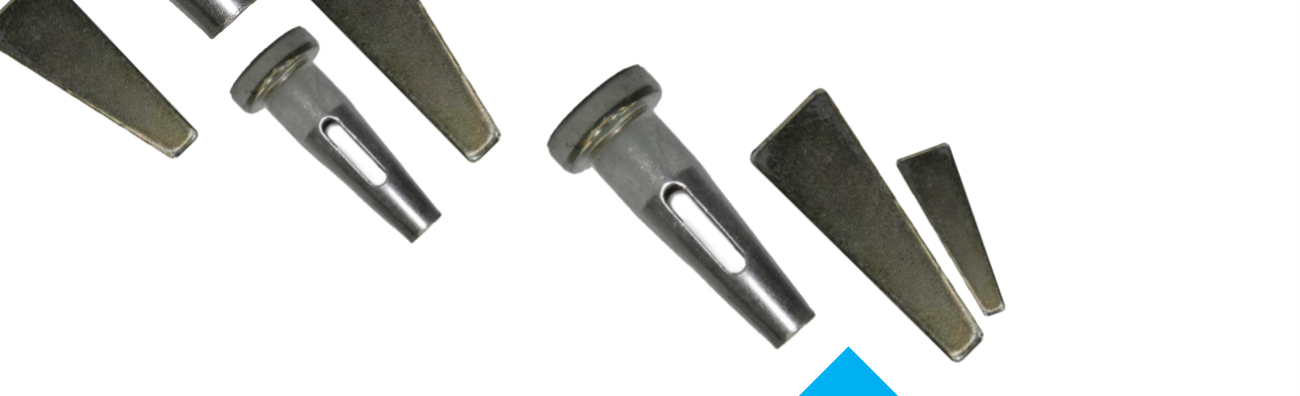

Standard panels are those of rectangular/square shape of various sizes which are mostly used for slab or wall. Irregular panels are those of shapes beyond regular quadrilaterals, requiring tailor-cutting. They are used for staircase, slab/wall corners etc.

ProMold

OEM Aluminum System Formwork

And Steel Formwork

Metals are something that we have been playing around in the last 28 years. From structure steels to small metal components, from mega towers to a roadside garbage bin, we challenge ourselves to be the best metalwork fabricator in the industry. Ever evolving our factories manufacturing capability on top of quality, in 2013 our specially designed formwork OEM production line goes live, and we proudly name it ProMold. The brand is set to assure clients about its dedication to the OEM collaboration: to supply formwork at high quality and to have clients’ best interests at heart.

Fully play

Your

Role

|

Program’s in-house workshops cover completely its fabrication processes. From cutting, bending, punching, welding to pretreatment and even powder coating. This comprehensive facility allows Program to have production quality strictly controlled and managed. |

||

Fabrication Workshops In fabrication workshops, jobs include: laser cut, plasma cut, water jet cut, punching, welding, polishing etc. |

Powder Coating Form works could be powder coated within Program's factory which hosts a dust-free coating workshop. |

Trial Installation Inside the factory, Program reserves spacious outdoor area for project trial installation where residential, hotel or office projects are able to be installed. |

|

Right machines enhance the quality of fabrication and improve operation effectiveness. Program strategically invests in importing high performance machines to its production lines. This benefits clients who value product quality. Here are some examples of machines: |

||

|

Cutting: CNC cutting allows precise and efficient cutting. |

Punching: CNC punching enhances the precision of hole alignment. |

Robotic welding: To guarantee welding point are precisely located and beads are made to requirement. |

Program nurtures engineers for the development of its aluminum formwork production line - ProMold. Engineers in Program work in metal fabrication industry for decades. Their experiences and dedication to learn clients’needs and requirement contribute enormously to the quality of formwork supplied by Program.

To support its growing global demand, Program invested in its state-of-art production center in Zhuhai, China. The factory is of 60,000 m2 housing around 350 staff, 3 factory buildings, 1 office building and 1 leisure & dormitory building for staff. Biggest factory in China? No. Up to international standard? Absolutely.

A Green, tidy and safe working environment is what Program offers our manufacturing workers. Should efforts have been recognized by governments and organizations.

- ISO 90001, 14001, OHSAS 18001

- Green Manufacturing Network by Hong Kong Productivity Council

- Green Medal, Hang Seng Bank Pearl River Delta Environmental Award

- HSBC Green Achievement Award Merit

- Cleaner Production, Hong Kong Environmental Protection Department

- Hong Kong – Guangdong Cleaner Production Partner, HK Environmental Bureau

- Environmental Excellence Award, Hong Kong Environmental Campaign Committee

Program encourages clients, organizations and institutions to learn about its factory and the industry practice as a means of exchanging information. If you are ready to learn something about the latest fabrication technologies, come visit us.

|

|

Supply | Supply&Service | OEM

We value collaboration with different parties to make our clients’ jobs easier. Message us for your proposal.

Aluminum Construction Formwork

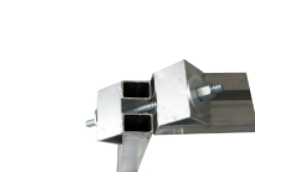

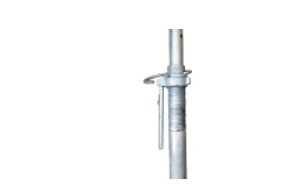

Aluminum system formwork is a reliable and easy-to-use equipment comparing to timber formwork. Workers can manage to learn the installation process and skills in short time, thanks to brands’ efforts into simplify designs. Generally, aluminum system formwork comprises 4 systems showing on the right.

Features

• Eco-friendly, reusable for 300+ times

• Precision molding and fast installation

• Simple system requiring no special techniques

• Light and easy to handle without a crane

• Smooth surface of concrete finish

• Cost effectiveness

Aluminum system formwork is applicable for a wide variety of building constructions for instance, Commercial/mall, Office Tower, Residential, Resort and Hotel, Health and Education, and Transportation.

It is highly recommended when projects are:

- Mass construction: constructing numbers of identical resort house;

- Highrise: office or hotel tower

- Facing limited construction time

Project Highlight

Comwell Garden | Comwell Group

Developed by the leading property development group Comwell, the Comwell Garden is located in Doumen, Zhuhai China. Program supplied aluminum formwork for the two new residential buildings accounting for about 2,820 m2. Apart from manufacturing and trial installation, Program’s engineers and project team assisted in formwork design. It was a great experience and the formworks were delivered on time of satisfactory quality.

Project Highlight

Comwell Garden | Comwell Group

Developed by the leading property development group Comwell, the Comwell Garden is located in Doumen, Zhuhai China. Program supplied aluminum formwork for the two new residential buildings accounting for about 2,820 m2. Apart from manufacturing and trial installation, Program’s engineers and project team assisted in formwork design. It was a great experience and the formworks were delivered on time of satisfactory quality.

Project Highlight

The Charm | Vanke

Thanks for the trust and consecutive supports from Vanke, ProMold again is awarded for participating in the development of Vanke’s branded residential property The Charm in Kunming, China. The Charm Kunming is the 12th project covering construction area of 2 million sqm.

Project Highlight

Studio City Macao | Melco Crown

Studio City Macao is the first leisure resort in Macao to include theatre and television and film production facilities. This Las Vegas-alike casino of 6,000,000 square feet comprises more than 400 gaming tables, shopping malls, high-end restaurants, and world-class hotels in Asia. Program supplied aluminum formwork for the construction of the hotel towers.

Project Highlight

The Pine Lake | Vanke

The Pine Lake is currently, the only society with comprehensive facilities located in the centre of economic zone in Dongguan, China. Vanke, the leading property development group awarded ProMold to provide about 3,911 sqm aluminum formwork for the project. ProMold is honored to be part of this developed-to-be environmental friendly project which matches ProMold's green image.

Project Highlight

Huaguoyuan | Guiyang, China

Huaguoyuan is going to be the busiest and biggest urban district with comprehensive social facilities for residents and commercial activities. It is developed by Homnicen Group with a team comprising design firm, development company etc. The 406 meters high twin tower will become the iconic building inside Huaguoyuan as a world class centre for shopping, office hotel, etc. Program is honored to fabricate aluminum formwork for the construction of the east tower.

Project Highlight

To Kwa Wan Regal Hotel

Kee Yiu Construction Engineering Ltd

To Kwa Wan Regal Hotel is co-developed by Regal Group and Paliberg which is targeted to open in season one 2016. The hotel will be 22 floors with 340 rooms to meet the demand of visitors to Hong Kong. The hotel offers comprehensive services to guests and thus its building design has to include various facilities. This becomes a challenge for aluminum formwork manufacturing as many irregular shapes were unavoidable. For the project as a whole, the challenge is solved at the factory which contributes to the smooth project flow on site.

References

If striving for the best finish and fine details is your thing, guess we are the manufacturer that you would probably love to talk with. Program is proud of gaining credits and supports from clients who consecutively demand high quality products from Program since 1987. For every product produced in Program’s factory, the quality must be as high as it was promised to clients. We are only released when problems are solved, as we care to build what clients’ dare to dream.

Program has successfully gained inclusion in the list of qualified tenders of various public transport utilities, government departments, hospitals, schools and construction companies. Meanwhile, it works closely with architectural and surveying firms

|

Government

|

1. Buildings Department Registered General Building Contractor, Registration No. GBC 102/98

2. Home Affairs Department (HAD) Approved Contractors – Hong Kong and Kowloon District 3. Hong Kong Housing Authority Approved Building Maintenance Contractor. (M1) 4. Hong Kong Housing Society Approved Contractor. (Building Maintenance and Improvement Works) 5. Registered Subcontractor of Voluntary Subcontractor Registration Scheme (Registration No.: R00600) 6. Urban Renewal Authority Approved Contractor for Repair/Maintenance Works (Former Land Development Corporation) 7. Works Branch Development Bureau, Approved Contractors for Public Works List I, Buildings Category (Group A) 8. Works Branch Development Bureau, Approved Suppliers of Materials and Specialist Contractors for Public Works (Structural Steelwork Category) |

|

Public Utilities and Private

|

|

|

Technology-painting

|

|

|

Corporate Social Responsibility

|

|

|

|

| Lighthouse Club Hong Kong | Macau Society of Metal Structures | China Formwork and Scaffold Association |

Buildings Department Registered General Building Contractor, Registration No. GBC 102/98

Electrical and Mechanical Services Department Registered Electrical Contractor, Registration No.: 013134

Home Affairs Department (HAD) Approved Contractors – Hong Kong and Kowloon District

Hong Kong Housing Authority Approved Building Maintenance Contractor. (M1)

Hong Kong Housing Society Approved Contractor. (Building Maintenance and Improvement Works)

Registered Subcontractor of Voluntary Subcontractor Registration Scheme (Registration No.: R00600)

Urban Renewal Authority Approved Contractor for Repair/Maintenance Works (Former Land Development Corporation)

Works Branch Development Bureau, Approved Contractors for Public Works List I, Buildings Category (Group A)

Works Branch Development Bureau, Approved Suppliers of Materials and Specialist Contractors for Public Works (Structural Steelwork Category)

CLP Power HK Ltd. Approved General Contractor/Supplier

Macquarie Goodman Asia Limited Approved Contractor

MTR Corporation Limited Permanent Lists of Qualified Contractors for Operations Projects (Building and Refurbishment Works, Civil Engineering, Metalwork and Signage)

Standard Chartered Bank (Hong Kong) Limited, Approved Contractors and Suppliers

Swire Properties Management Limited Approved Contractors (Building/ Cladding/General Building Works)

International Standards Award

ISO14001 Environmental Management System

ISO9001 Quality Management System

OHSAS18001 Occupational Health and Safety Management System

Membership of Shenzhen Hi-tech Industry Association (No.: 0726)

The Chinese Major Corporate Membership of US-China Exchange Association

Shenzhen Association for Quality Membership (No. 7507)

Vice President and Member of Shenzhen Long Gang Enterprise Confederation and Shenzhen Long Gang Entrepreneur Association

Membership of the Customs Declaration Association, Shenzhen

Membership of the China Building Decoration Association (Cert No.: 4400111)

Hong Kong – Guangdong Cleaner Production Partner (Manufacturing)

Orica Coatings Registered Applicator

Caring Company

FHKI CSR Recognition Scheme

Friends of EcPark

Green Manufactruing Network Certificaate

Pearl River Delta Environmental Awards-Green Medal

Hong Kong Q-Mark Product Scheme

Membership of Construction Industry Institute Hong Kong

HSBC People Caring Award Excellence 2013

HSBC Green Achievement Award Merit 2013

HSBC Community Engagement Award Merit 2013

Term Contract for Alteration and Addition Works at Sha Tin Racecourse of Hong Kong Jockey Club 2012-2014

MTRCL Contractor Safety Performance Award 2012-2013

Double Distinction Award and Quality Advancement Award for Foreign-owned Corporate in China

Appreciation Letter for Evironmental Initiatives and Excellence

Industry CARES

Hong Kong Q-Mark Product

Friends of EcoPark

The Hong Kong Council of Social Service

Hong Kong Q-Mark Product

Enhancement of Flood Protection Measure for MTR Stations and Ancillary Building Entrances

HKHA Quality Public Housing Construction and Maintenance Awards

MTRC Partnering Award - Civil Works Project (Safety Classification 2)

MTRC Contractor Safety Performance Award - Civil Works Project (Safety Classification 1)

Hang Seng-Pearl River Delta Environmental Awards

C7326-06C: Station Commerical Works for SWH, QUB, LCK, WTS and NTK

Supply and Installation of Vitreous Enamel Cladding System for the Extension and Improvement Works to Macau Stadium

C4423.67B-003C: Station Ceilings - Batch 1B

Environmental Encouragement Award

15 Continuous Accident Free Months

C4423.42-01C: Full Modification for Central Station Entrances E & F, J1 & J3

C4423.42-01C: Full Modification for Central Station Entrances E & F, J1 & J3

Close

Close